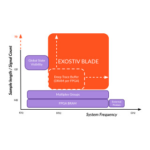

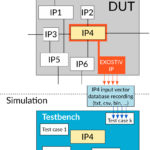

RTL or Netlist flow? EXOSTIV Dashboard Core Inserter and Exostiv Blade Core Inserter propose 2 alternate flows* for inserting EXOSTIV IP and Exostiv Blade IP into the target design: the ‘RTL flow’ and the ‘Netlist flow’. With the RTL flow, the IP is generated as a RTL

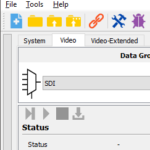

Read more →Exostiv – Video Compilation Please find below a compilation of the videos about Exostiv.

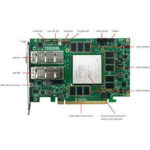

Read more →Announcing… EXOSTIV for Intel FPGA Using Intel FPGA? We have exciting news for you: EXOSTIV will soon support Intel FPGA! Please check the pictures above and below – this is EXOSTIV working with the ‘Attila’ dev kit of our partner, Reflex-CES, equipped with one Arria 10 GX

Read more →EXOSTIV is there – and it is not a monster As you might have noticed, EXOSTIV for Xilinx is now released. With the launch, I have been on the roads to demonstrate the product. The good thing about meeting FPGA engineers is the flurry of questions, ideas

Read more →‘My FPGA debug and verification flow should be improved…’ In my last post, I revealed some of the results of our recent survey on FPGA. These results depicted a ‘flow-conscious’ FPGA engineer, using a reduced mix of methodologies in the flow and very prone to going to

Read more →Does FPGA use define verification and debug? You may be aware that we have run a first survey on FPGA design, debug and verification during the last month. (By the way, many thanks to our respondents – we’ll announce the Amazon Gift Card winner in September). In

Read more →